Description

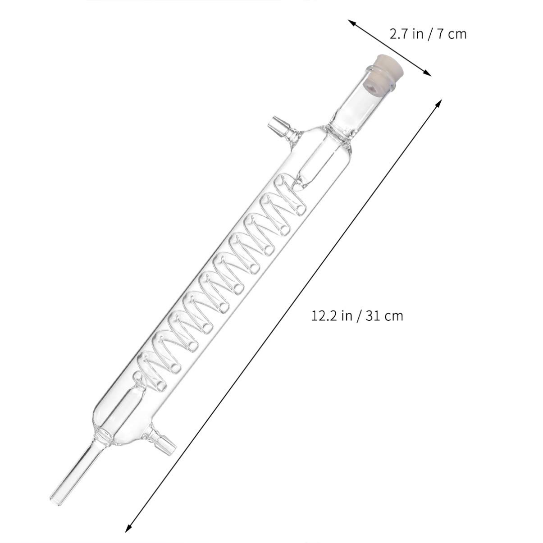

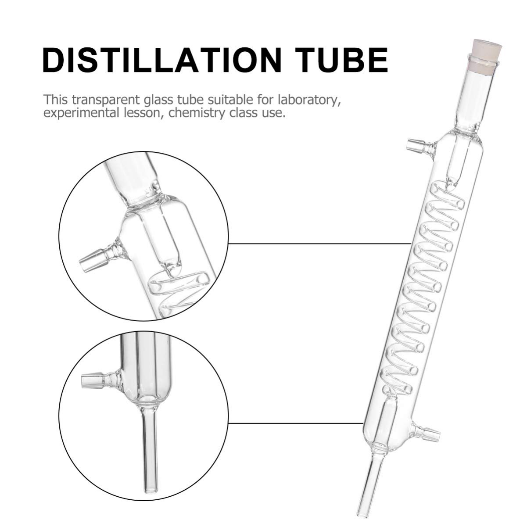

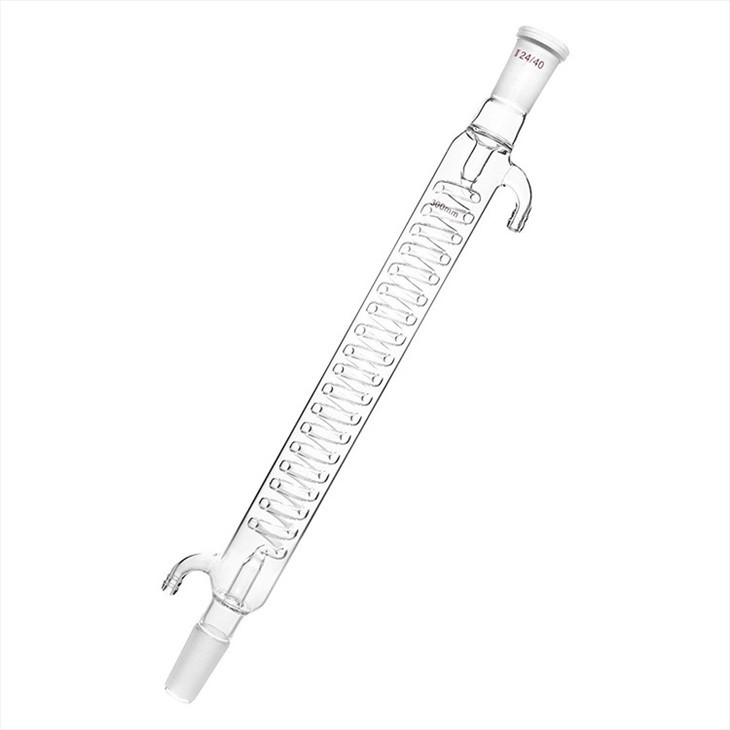

Coiled tube condenser for efficient cooling and condensation of gases or vapors. Widely used in industrial applications and laboratories. Inner tube is coiled in a spiral shape, increasing the surface area for heat exchange. Effective in converting high-temperature gases into liquid form. Ideal for air conditioning, refrigeration, and chemical processing.

Product Features:

- Condenser with coiled inner tube.

- Cooling area: 2.3mm, 2.7mm, 3.3mm, 4.7mm, 7.0mm, 8.2mm.

- Glass condenser: Borosilicate Glass.

Application:

1. Air conditioning systems

2. Refrigeration equipment

3. Chemical processing plants

4. Industrial equipment

5. Laboratory setups

6. Heat exchangers

7. Power plants

8. HVAC systems

9. Petrochemical industry

10. Pharmaceutical industry

Product Specifications:

Condenser with coiled inner tube,Graham Boro 3.3 Class

| CODE | Size/mm | Dia of mouth/mm | Effectivelength/mm | Totallength/mm | Weight/g |

| 5023 | 200.608696 | 14 | 200 | 300 | 175 |

| 5023 | 200.730769 | 19 | 200 | 305 | 186 |

| 5023 | 200.827586 | 24 | 200 | 305 | 209 |

| 5023 | 300.730769 | 19 | 300 | 405 | 281 |

| 5023 | 300.827586 | 24 | 300 | 415 | 300 |

| 5023 | 300.90625 | 29 | 300 | 445 | 316 |

| 5023 | 400.730769 | 19 | 400 | 520 | 364 |

| 5023 | 400.827586 | 24 | 400 | 510 | 360 |

| 5023 | 400.90625 | 29 | 400 | 535 | 379 |

| 5023 | 500.730769 | 19 | 500 | 610 | 445 |

| 5023 | 500.827586 | 24 | 500 | 620 | 460 |

| 5023 | 500.90625 | 29 | 500 | 640 | 482 |

| 5023 | 600.730769 | 19 | 600 | 720 | 530 |

| 5023 | 600.827586 | 24 | 600 | 730 | 550 |

| 5023 | 600.90625 | 29 | 600 | 750 | 555 |

Product Advantages:

1. Enhanced Heat Transfer: The coiled inner tube design of the condenser maximizes the surface area for efficient heat transfer, leading to faster and more effective cooling and condensation of gases or vapors.

2. Compact Design: The coiled inner tube condenser offers a compact and space-saving solution, making it suitable for installations in tight spaces or where space is limited.

3. Versatile Applications: This condenser is widely used in various industrial applications, laboratories, air conditioning systems, and chemical processing plants, showcasing its versatility and adaptability to different environments.

4. Efficient Cooling: The coiled inner tube condenser ensures excellent cooling performance, allowing for the conversion of high-temperature gases or vapors into liquid form efficiently and reliably.

5. Reliable Operation: With its reliable and robust construction, the coiled inner tube condenser provides long-lasting performance and is designed to withstand demanding industrial conditions.

6. Cost-Effective: The efficient heat transfer and cooling capabilities of this condenser help save energy and reduce operational costs, making it a cost-effective solution for cooling and condensation processes.

7. Easy Maintenance: The design of the coiled inner tube condenser allows for easy maintenance and cleaning, ensuring optimal performance and prolonging the lifespan of the equipment.

8. High Heat Transfer Efficiency: The coiled inner tube design ensures a high heat transfer coefficient, facilitating quick and efficient heat dissipation from the gases or vapors, resulting in faster condensation.

9. Improved Performance: The coiled inner tube condenser enhances the overall performance of cooling and condensation processes, providing reliable and consistent results.

10. Durability: The condenser is manufactured using high-quality materials, ensuring durability and longevity, even in harsh operating conditions.